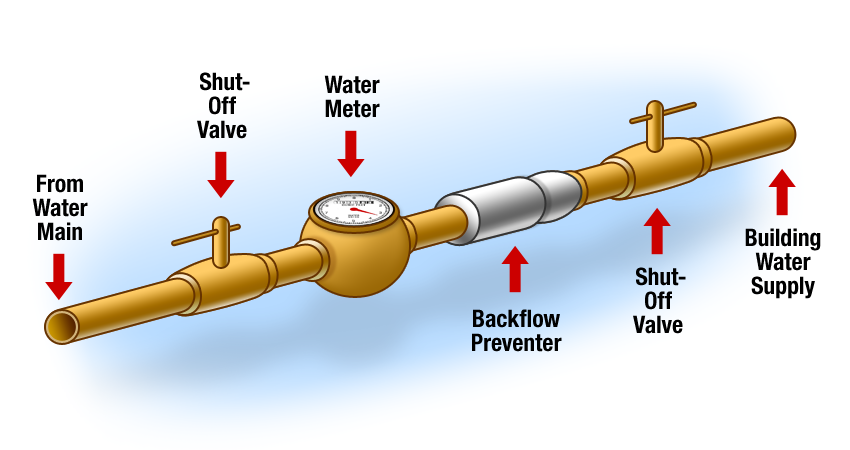

When your potable water mixes with undesirable liquids, dirty water or gas and reverses its flow back into your water supply, this is called backflow. It’s typically caused by backpressure or back-siphoning and can result in contaminated water flowing into areas where you expect the water to be clean. This includes your swimming pool, lawn irrigation system and well water, for example. A backflow preventer is an assembly that stops water from reversing and contaminating a clean water supply.

Winter is usually a very rough season when it comes to outdoor backflow preventers. The design of these assemblies has changed to make them less susceptible to freezing conditions. Initially, they were made of heavy materials with thick walls that were pretty durable. The disadvantage is that they were overly large, awkward and hard to handle because of their immense weight. In response to market demand, manufacturers modified the design and materials used so that backflow preventers are now smaller and a lot lighter. Cast iron has also been replaced by brass or hard plastic. The wall thickness that was once very thick is now pretty thin.

Backflow Prevention

While modern backflow preventers are still efficient, they can become damaged or unstable when the temperature dips a bit below freezing temperature. Even the heaviest and thickest of the backflow prevention materials are no match for the overwhelming pressures of freezing water.

Some of this damage can be repaired by having a plumbing contractor replace the parts, but most often this expansion caused by freezing distorts the assemblies in a way that is too immense, and no reasonable repairs can return the unit to a satisfactory condition. So most residential installations of these new and improved backflow preventers are required for lawn irrigation, pools or water wells and are usually installed outside. This assures total protection from contamination on commercial customers, which will save you from having to make a call to emergency plumbing services and protecting the preventers from freezing.

Units used for lawn irrigation and swimming pools are usually only active in late spring, summer and early fall. They can be taken out of service when they’re not in use. These are sometimes purged with air that removes water, then left in place for the entire winter. This is usually accomplished by opening the units to drain out water or by forcing in the water’s compressed air. This method is not without risk, though, because both of the methods can leave water in the unit and high velocities of compressed air can damage parts.

Other options that are available is to remove the unit and then store it inside a warm location. Recently, some manufactures have figured out how to design back flow devices to make this method easier. Some backflow preventers are designed with a module that contains check and relief valves that can easily be removed and stored for the winter. When removal is impossible, protection must be provided. Enclosures are available that offer great protection from freezing as well as vandalism. Generally, they’re made from aluminum and or fiberglass. They’re insulated and secured with a concrete slab containing a drainage port within the enclosure wall. Very careful consideration needs to be given to the drainage port during the landscaping process to avoid covering up the port. A standard is available that assures the enclosures have been lab tested and will then protect against specific conditions.

Backflow preventers are typically tested to ensure that your heat source meets all of the above freeze protection conditions, have been lab tested and are safe, so that you can provide a specific level of performance. Look for labeling on heat sources that are certified by an independent and safe product listing, as well as a certification agency, that says the backflow prevention device is for use in all conditions, especially damp and wet locations.

Backflow is the reversal of water flow from its normal or intended direction of flow. Whenever a water utility connects a customer to the utility’s water distribution system, the intention is for the water to flow from the distribution system over to the customer. However, the flow of water has the possibility of being reversed from the customer back into the distribution system. If these cross-connections exist within the customer’s plumbing system when back flow occurs, then it’s possible to contaminate the entire public’s water supply.

For reliable backflow preventer freeze protection, contact A-1 American. We handle backflow prevention device repair, replacement, installation and removal throughout the Hampton Roads region. If you discover backflow in your potable water system, don’t wait. It’s an emergency. Call now. We’ll send someone out right away. Call today 757-425-2400