A-1 American performs certified back-flow testing to verify that the movement of water in your back-flow prevention device is traveling in the right direction rather than in the reverse direction. It is a serious health risk if your drinkable water is contaminated with waste water. Backflow can contaminate the water in a building, or even on an entire block.

Back Siphonage

Back-flow can occur in two different ways. The first way is when the supply pressure is lowered below that of a system, called back siphonage. Back siphonage occurs when the water supply is interrupted or drained down. This is opposed to back pressure, which occurs when the water supply pressure is lowered below that of the system. Learn a little more about it here.

Testing

Testing of all back-flow prevention devices is annually enforced by the federal government. As certified back-flow technicians, A-1 American technicians are qualified to test your back-flow prevention device. We test for leaking or failing parts, and keep records of your forms in compliance with city, state, and federal obligations.

- Air Gap (To protect against back pressure)

- Back-Flow Prevention Device Test

- Check Valves

Regulatory requirements

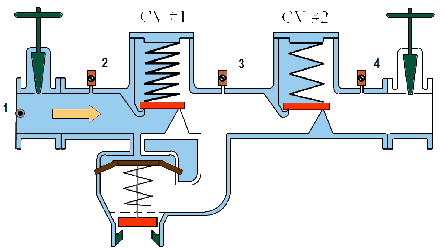

To prevent contamination due to back pressure, many health regulatory regimes require an air gap or mechanical back-flow prevention assembly between the delivery point of mains water and local storage or use. Where submerged mains inflow is permitted, a back-flow prevention assembly is required, which protects the potable water system from contamination hazards.A check valve is a common form of back-flow prevention, but more complex devices may instead be required.

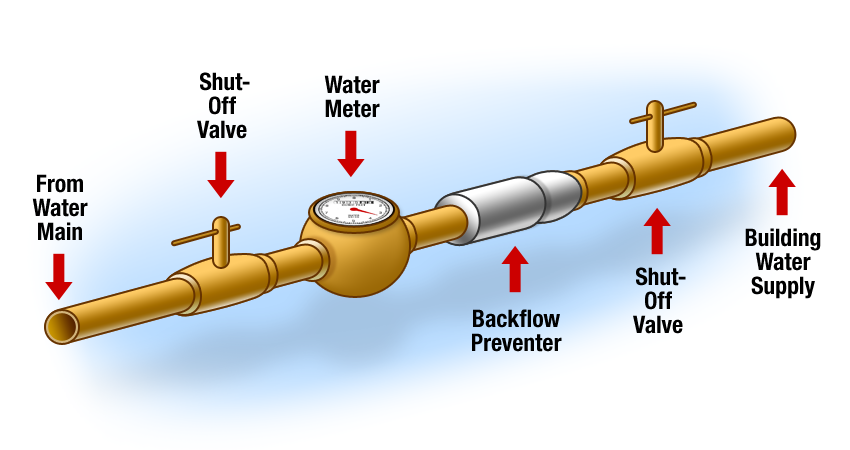

In many countries. approved back-flow prevention assemblies are required by law, and must be installed in accordance with plumbing or building codes. A typical back-flow assembly has test cocks and shut-off valves, and must be tested when installed, if relocated or repaired, and also on a periodic basis.

In the US, the Environmental Protection Agency (EPA) holds local water suppliers responsible for maintaining a certain amount of purity in potable water systems. Many states and/or local municipalities require annual testing of back-flow prevention assemblies. In most cases, the law requires a double check (DC), Reduced Pressure Principle Device (RP) device, or an air gap when back-flow prevention is mandated.

One of the greatest risks to contamination of your drinking water may be you and/or your neighbors. Experts recognize that the manner in which end users improperly connect to, under protect, and/or utilize the water are the leading causes of contamination.

Contamination of the drinking/potable water system results from back-flow through cross-connections with private plumbing fixtures, appliances, water utilization equipment, or in general, under protected water system outlets. A cross-connection is the physical connection between the potable water system and an end use where a potential hazard exists. Back-flow is the undesired reverse flow of contaminants into the potable water from such hazards and is typically driven by common but unfavorable hydraulic events in either the public or private water distribution system.

Over the last 30 years or so back-flow prevention assemblies have been installed on residential properties to mitigate the hazards of cross connections. A back-flow prevention assembly is a one-way appurtenance (an assembly of check valves), that only allows water to flow in the desired direction and physically impedes reverse flow. However, there is a limited life expectancy for the working components of a back-flow prevention assembly. These assemblies can fail for a number of reasons: sediment or debris can block their proper function, unprotected cross-connections may exist stemming from an oversight during original construction, or detrimental plumbing.

Annual testing of back-flow prevention assemblies is required to ensure proper functionality. The test is a physical measuring of pressure differentials to ensure the assemblies’ internal working components are still functioning properly. Most plumbing codes require that all home and business owners maintain records pertaining to their testable back-flow prevention set up. If you are a home or business owner and this is not part of your current routine and records, now is a great time to get started. Back-flow contamination is a serious problem and the consequences of a back-flow event can be dire, including serious property damage, illness, and even death. The back-flow contents can and will contain hazardous content. If you are found responsible for a cross-connection, whether unprotected, improperly protected or improperly maintained, you may be held financially liable for any of the mentioned consequences, cited with fines. To prevent that, it is a good idea to keep records and have your back-flow prevention tested and maintained, being that changes may have been made to the property over time. As a result, federal and state regulations require purveyors to have a viable cross-connection control program (CCP) to ensure that adequate back-flow protection is not only in place, but that it is also maintained in good working order.

FAQ

1. Why choose A-1 American?

At A-1 American, our professionally trained technicians are up to date with the newest technologies and procedures to best handle your Back-Flow Prevention Testing. With years of experience and knowledge in this matter, don’t trust other companies that claim to have the same certifications and experience! A-1 American will provide the best services possible.

2. What is Back-flow?

Simply put, back-flow is defined as the unintentional reversal of the normal direction of flow in a potable water system that may result in the pollution or contamination of the system by a liquid, gas, solids or mixtures. Back-flow is anywhere contaminated water has the chance to mix with clean water.

3. Why does the Back-flow Device have to be tested yearly?

A Back-flow Preventer is a mechanical device, and like any mechanical device, it will fail. Virginia Beach Code specifies that every back-flow prevention device must be tested at least yearly to verify its operation. Failure to do so could allow a back-flow event to harm people and/or property.

4. What does the Back-flow Test involve?

The back-flow test is fairly simple. Every testable back-flow device has test ports built into it to allow yearly testing. An A-1 American back-flow technician will connect a test kit to the device and verify proper operation. All water downstream of the back-flow device must be shut off to perform the test. Our technicians are educated in the required process to preform the testing.

5. Do I need to be home when you come to do Back-flow Test?

If your device is outside, then the answer is no. Just leave us the back-flow paperwork you received from the Health Dept or City and we’ll do everything else. If you choose to want to be home, we can work around your schedule! No problem. Though, if your device is inside, than someone will need to be home to let us in.

6. What is failure rate and what are common failure modes?

Several factors influence the lifespan of a back-flow device. These factors include water pressure, water quality, frequency of use and installation environment. About 5% of tested devices will have a problem. Most problems are simple and are caused by worn O-rings, cut seals or broken springs. Severe problems such as cracked castings and shattered poppets are usually caused by exposure to freezing temperatures. We offer complete repair service on any device. But being in Virginia Beach we find that it is not common to have exposure to freezing temperatures.

7. My Back-flow Device is leaking from the bottom relief port. Is it bad??

The relief port is made to discharge water as the back-flow device does its job. If it only drips occasionally or has a damp spot on the floor underneath it, it’s probably okay. However, if it is leaking constantly from relief port, then something is wrong. Click here to call us for recommendations!

8. Why are some back-flow devices installed inside and others installed outside?

It all depends on the installer and what the device is going to protect. Almost all commercial back-flow preventers are inside. Back-flow preventers connected to residential irrigation systems can be inside or outside; however, the current trend is to put them outside.

Make sure your potable water is fresh.

Schedule your back-flow test with a qualified A-1 American technician.