PEX Plumbing, or cross-linked polyethylene, is one of the leading water supply piping systems available. It has many advantages over metal piping or even plastic piping, such as PVC. Some of the features of PEX Plumbing are its flexibility, its resistance to corrosion and decay, and its resistance to chlorine. In addition to its functionality, PEX Plumbing is also faster and easier to install, since it has fewer connections and fittings that need to be adjusted.

PEX Plumbing was introduced to the U.S. around 1980, but it originated in Europe almost a decade before. Since its introduction to the U.S., PEX has quickly become popular, replacing copper piping in most applications.

How It’s Made

PEX tubing is actually manufactured from a cross-linked high density polyethylene(HDPE) polymer. There are 3 different methods for cross-linking the HDPE, but the main idea is that the HDPE is melted and continuously extruded into the tube. This gives it a better lifespan than other water and sewer pipe materials, including PVC.

To help differentiate between PEX tubing types, the components are generally coded to make sure the correct tubes are being used. You can view all PEX Codes here.

Advantages of PEX Plumbing

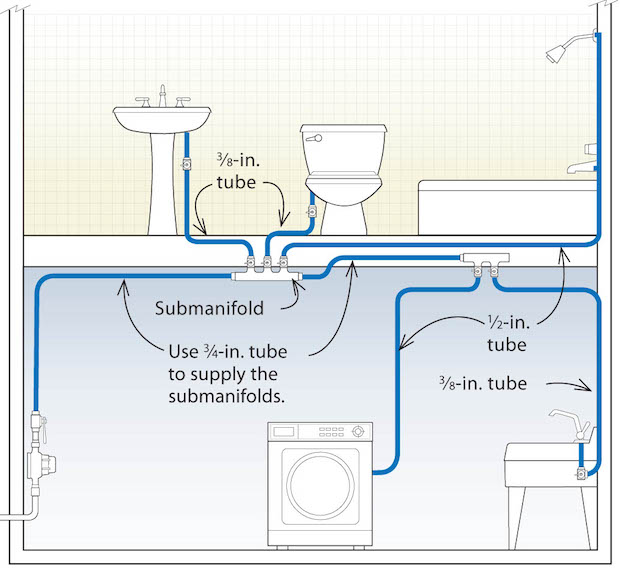

Flexibility - Due to its flexibility, PEX tubing can be rolled into spools, which allows for longer pieces of PEX to be easily packaged and shipped. When it comes to metal piping, each pipe must be cut into more practical lengths to ship, which requires more fittings and attachments to create the desired size and shapes. This allows for PEX tubing to be shipping at longer lengths which in turn cut down on manufacturing costs, shipping costs, and costs for fittings. Another advantage of this flexibility is that PEX tubing can be turned in 90-degree angles, which ends the need for elbow fittings.

Weight - PEX tubing is significantly lighter than most other forms, especially metals. This allows handling to be much easier, and cuts down on shipping costs. The obvious outcome of the weight difference is also that it allows PEX tubing to be installed much easier than all other forms of tubing, which cuts down on the cost.

Assembly - EX tubing on its own significantly cuts down the need for most attachments. It can be turned at a 90-degree angle, which ends the need for elbow fittings and connectors. A huge advantage to this point is that even when a connector or fitting need to be installed. There is no longer a need for soldering. This eliminates health hazards associated with lead-based soldering and associated acid fluxes. To make it simple, PEX tubing requires no torch or burning of any kind. This makes the job much safer for all plumbers.

Chemical Resistance - Unlike other forms of piping (such as copper) PEX resists most chemical build ups. This makes it extremely resistant to corrosion, due to scale build-ups or exposure to acidic water.

Temperature Control - PEX Plumbing tubes are much more resilient to freezing, and it also does not transfer heat the way that other metallic piping does. This allows for the conservation of energy as well as the decreased likeliness of the tubing cracking to do drastic temperature changes.

Noise Reduction - Unlike copper piping systems which create a “water hammer” noise as water rushes thru it, PEX tubing allows water to flow more freely which almost completely eliminates the sounds.

When replacing pipes, our A-1 American technicians use PEX plumbing repair technology for its ease of installation and state-of-the-art properties. for more information about PEX Plumbing, contact us today.